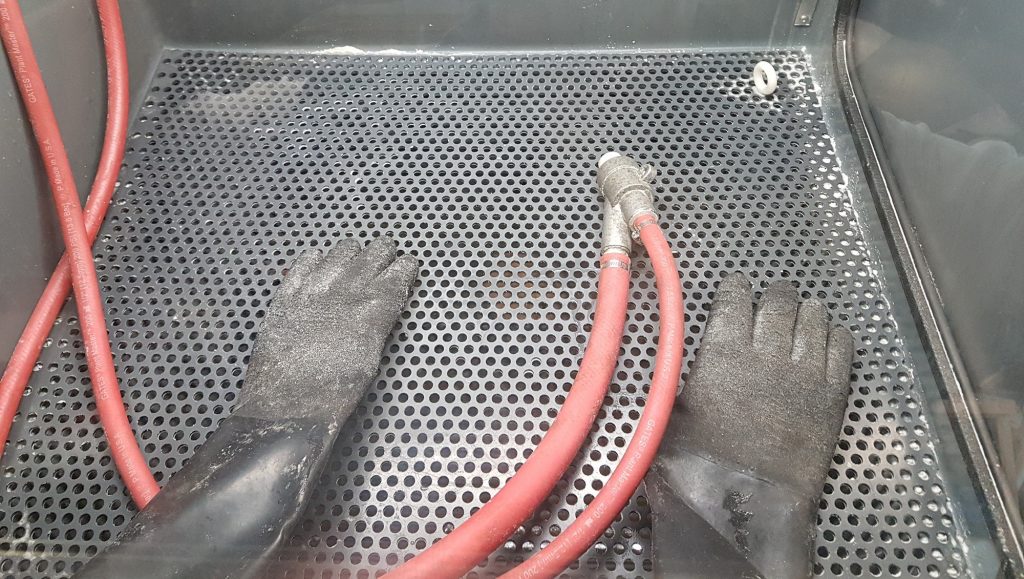

Vapour blasting uses a blast media, water and air to create a high pressure slurry. Parts are contained inside a cabinet and blasted with the slurry. The slurry drains into a sump and is filtered. The cabinet is designed and manufactured by Vapour Honing Technologies from the USA http://vaporhoningtechnologies.com/

The process is known as vapour honing, vapour blasting or wet blasting, we think that vapour honing provides a good description

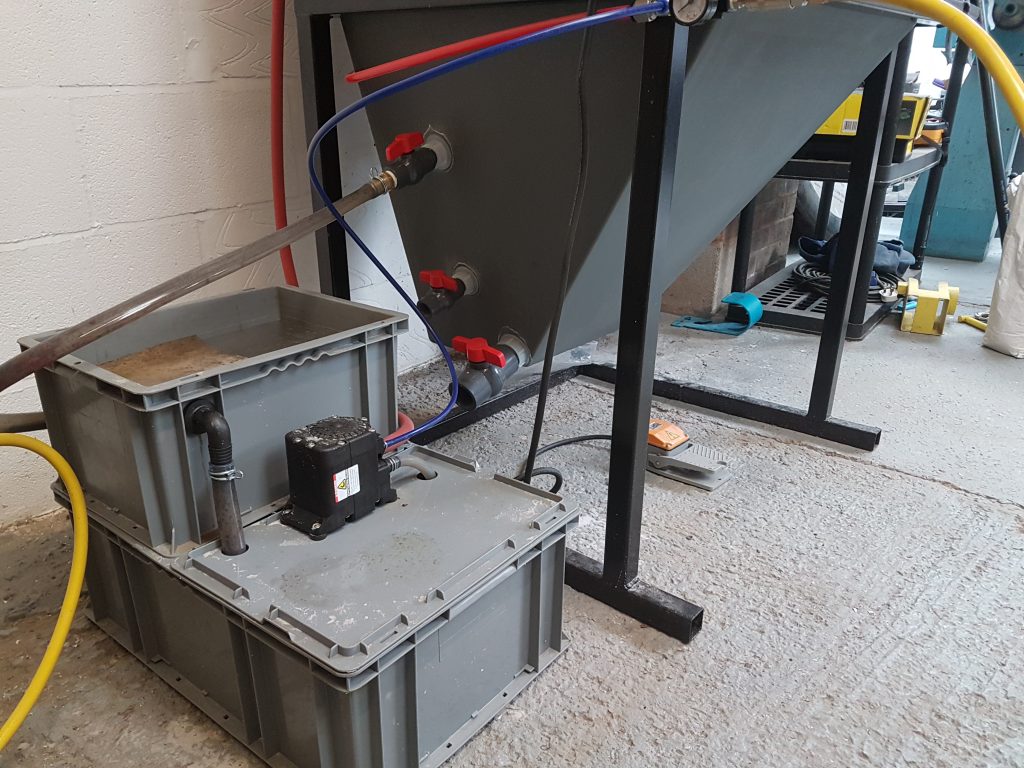

The slurry is filtered and recycled. This recycle phase is important for environmental reasons. We do not discharge polluted water into the drainage network

Vapour blast cabinet recycle system

Powdered glass is used for most restoration projects as it does not remove surface material or change dimensions. The part is cleaned and (using powdered glass) provides an attractive polished finish. This is ideal for engine parts and non-metallic items. Glass media may not remove factory applied coatings although some after-market coatings can be removed, so it is ideal for most restoration work

The process may not remove synthetic material such as gasket cement. It is perfect for parts with a variety of materials such as carburretors. It will clean alluminium, brass and rubber components effectively. For removal of coatings and for surface preparation pre-coating, Alluminium Oxide may be used

More angular coarse media such as ceramic beads can be used for removal of paint and other surface coatings. It can’t be used on machined surfaces as it is too aggressive.